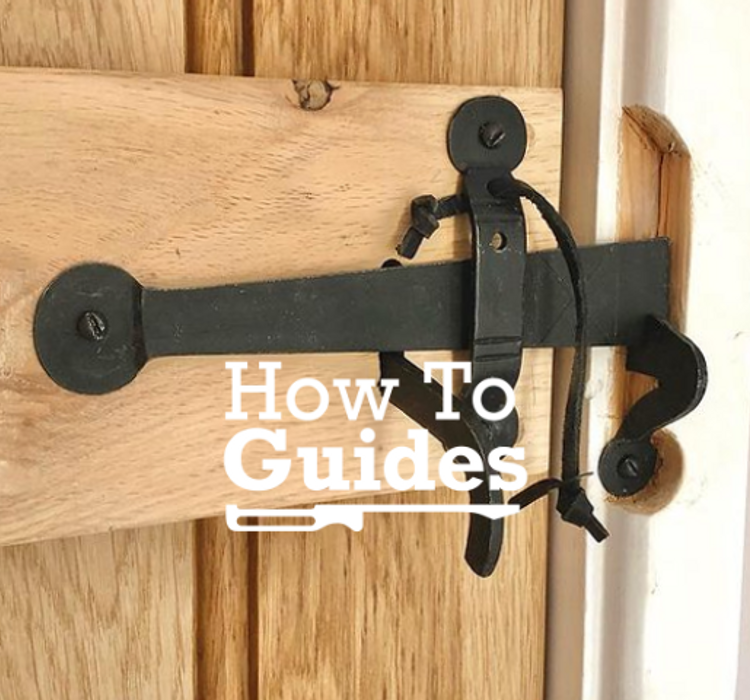

Ledge and brace doors can be left unfinished, however natural oak marks and stains easily. The marks will be especially prevalent around the latch area and at the bottom of the door where there is a tendancy to kick open or closed with feet. Hand forged latches and hinges are traditionally coated in a thin layer of clear bees wax, to maintain the metal and prevent oxidisation, but this can also cause a problem with the wax transferring from the metalwork to the wood, making difficult to remove marks.

As much as I love the look and feel of a natural oak door, I would recommend using some kind of coating. There are essentially three available choices:

- Danish Oil/Hard Oil

- Wax

- Sanding Sealer/Wax Combination

1. Danish Oil/Hard Oil

The main advantage in using Danish oil is that it soaks deep into the timber. I suggest applying three coats, leaving 24 hours between applications. Between each coat, use a very fine sand paper to knock the finish back in preparation for further application. The disadvantage in using this coating is that oil can make the oak look a little dark and in some cases orange, and secondly the wood will never feel smooth to the touch, this is due to the fact that the oil will slightly lift the grain.

2. Wax

There are a vast range of soft waxes available in many shades and colours. I would strongly recommend sampling a few on scrap timber first, to make sure you are happy with the colour; once it is applied, it will prove almost impossible to remove. The secret to success with soft wax is to apply it in thin layers, leave for a short time then buff to a shine. You can apply as many coats as you need, but remember it will darken slightly after each application. The one disadvantage of using wax is that it can easily mark if liquid is spilled onto it.

3. Sanding Sealer/Wax Combination

For best results I recommend first sealing the timber with a high build sanding sealer, applied with a spray gun. After the coating has dried, sand back with a very fine abrasive. This will seal the timber and give an extremely smooth finish. Then finally apply a thin layer of soft wax, Because the timber is sealed it will not darken, only the soft part of the grain will take on the colour of the wax - this is what we call the strike in the trade. The only real disadvantage of this system is that this is only a surface coating and if it gets knocked or scratched the treatment will be removed.

We have over the years used a company called Symphony East for all our coating solutions, the most professional and helpful bunch you could ever hope to meet.

Comments

Watch a professional carpenter show you how to hang a door and read our step-by-step guide.

Read Article